Nearly all CNC machine uses a Cartesian coordinate system based on an X, Y, and Z-axis. This system allows a machine to move in a specific direction along a specific plane.

#1 How CNC machines are classified based on control system features?

''Classified by the servo system, it can be divided into open-loop control system, semi-closed loop control system and closed-loop control system. Open-loop control system means that there is no detection and feedback device''

#2 What does a coordinate code communicate to a CNC machine?

''G codes describe the operation that the machine will perform. X, Y, and Z codes determine the cutting operation location. F and S codes set the feed and speed, T codes signal the correct cutting tool, and M codes complete other miscellaneous functions''

CNC MILLING COORDINATE SYSTEM

2 SLOT AND 4 HOLLS

PROGRAM NO. 1

N01G90G21M03S1000

N02G01X20Y20Z5F.25

N03G01Z-5

N04G01Z10

N05G01X20Y80

N06G01Z-5

N07G01Z10

N08G01X80Y20

N09G01Z-5

N10G01Z10

N11G01X80Y80

N12G01Z-5

N13G01Z10

N14G01X40Y40

N15G01Z-5

N16G01X50Y40

N17G01X50Y80

N18G01X40Y80

N19G01X40Y40

N20G01Z10

N21G01X60Y40

N22G01Z-5

N23G01X70Y40

N24G01X70Y80

N25G01X60Y80

N26G01X60Y40

N27 Z10

M30

PROGRAM NO. 2

ANGLE HOLL CUTTING

O0011

N01G90G21M03S1000

N02G16F2.00

N03G00X30Y0Z10

N04G01Z-5

N05G01Z10

N06G01X30Y30

N07G01Z-5

N08G01Z10

N09G01X30Y60

N10Z-5

N11G01Z10

N12G01X30Y90

N13Z-5

N14Z10

N15X0Y0

N16Z-5

M30

CNC Turning coordinate system

Program No. 1

O0007

N01G90G21

N02U0W0M03S1000

N03G00X0Z0

N04G01X30Z0

N05G01X30Z-20

N06G03X35Z-30R10

N07G03X40Z-50R20

N08G03X50Z-70R20

N09G03X60Z-90R20

N10G03X70Z-110R20

N11G03X80Z-130R20

N12G01X80Z-180

M05

M02

Program No. 2

O0008

N01G90G21

N02U0W0M03S1000

N03G00X0Z0

N04G01X30Z0

N05G01X30Z-20

N06G02X40Z-40R20

N07G01X40Z-50

N08G03X50Z-60R10

N09G01X50Z-80

N10G03X60Z-90R10

N11G01X60Z-140

N12G02X70Z-160R20

N13G01X70Z-200

M05

M02

Program No. 3

O0009

N01G90G21

N02U0W0M03S1000

N03G00X0Z0

N04G01X20Z0

N05G01X20Z-10

N06G03X30Z-20R10

N07G01X30Z-40

N08G01X40Z-40

N09G01X40Z-60

N10G02X50Z-70R10

N11G01X50Z-90

N12G02X60Z-100R10

N13G01X60Z-110

N14G02X70Z-120R10

N15G01X70Z-140

N16G03X80Z-150R10

N17G01X80Z-170

N18G02X90Z-180R10

N19G01X90Z-200

N20G03X100Z-210R10

N21G01X100Z-250

M02

M05

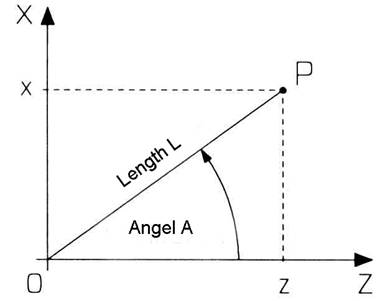

CNC Turning Coordinate System

Nearly all CNC machine uses a Cartesian coordinate system based on an X, Y, and Z-axis. This system allows a machine to move in a specific direction along a specific plane. Reduce the Cartesian system to its basics, and you have a familiar number line. One point on the line gets designated as the Origin.

1. What are the 3 coordinate systems?

There are three commonly used coordinate systems: Cartesian, cylindrical and spherical. In this chapter, we will describe a Cartesian coordinate system and a cylindrical coordinate system.

Coordinate system

A CNC program describes the work piece outline by indication of points in a coordinate system. Usually a right-hand coordinate system is used, but in certain cases also indication of polar coordinates can be used. Since turning acts with rotationally symmetric parts (mathematical: Volume body, which will be get through rotation of a piece of curve around an axle), a two-dimensional execution is sufficient. The X-axis shows in direction of the across support, the Z-axis coincides with the axis of rotation of the main spindle.

Machine zero point

The feed axles in along and transverse direction build the Machine coordinate (coordination) system. The machine zero point is given by the manufacturer and normally lies on the spindle axle at height of the chuck admission. To this coordinate system refers the control with its instructions.

Workpiece coordinate system

In a manufacturing drawing the zero point is on the reference element. That can be a front surface and the axis of rotation for e.g. So that one does not have to convert the dimensions during numerical control programming to the Machine coordinate system, one can determine a new workpiece zero point in the coordinate system by a zero shift (e.g. G54), to which all following data refer. This workpiece coordinate system can be selected by the operator freely and makes the simple conversion possible of drawing data to a NC-Program possible.

Absolute measure- Incremental measure

Coordinate data as absolute data refer to the zero point (e.g. move to the point X = 40mm Z =-50mm). The X-value indicates the diameter.

With an indication of incremental measure the values refer to the current position (e.g. move - 30 mm in Z-direction). In this case the X-value indicates the actual length of movement X-1 means a diameter reduction of two millimetres.

Tools

Since there are turning tools of most diverse kind, the control must get all relevant data for the work. Common denominator of all tools is the tool adjusting point. It is at the notice surface of the tool holder and coincides when inserting into the tool chuck with the tool reference point (see up). The control takes this point for the calculation of the tool movement.

In order to consider now the different tool dimensions now, a correction value memory is assigned to each tool in the computer of the machine, which contains the distances of the chisel point of the tool reference point. These values are measured either before the job or determined by a sample manufacturing. The length of the tool is the distance in Z-direction (lengthwise to the spindle axle). The transverse value of the tool is the distance in X-direction (transverse to the spindle axle). In addition the control needs the radius of the cutting edge and the work quadrant for the calculation of the radius correction.

For the production of a workpiece several different tools are usually needed. A tool magazine or a tool turret makes it possible to equip the machine with several preset tools. In the NC-Program the needed tool with it`s stored correction values will be called by the magazine number.

CNC Program structure

Program structure A NC-Program consists of individual sentences. These consist of individual words, which divide themselves in address and value. A sentence contains usually several words.

Frequent addresses::

N

record number

G

way conditions (circle, straight lines, rapid traverse)

X

X- coordinate endpoint

Z

Z-coordinate endpoint

F

feed rate

S

spindle speed

T

tool number

M

machine function

Some instructions apply only to the sentence, in which they are programmed. In addition, there are some which are valid over several sentences. The instruction “G00” (rapid traverse), e.g. is so long valid, until it is overwritten by another instruction. One speaks then of a modal effective instruction.

Work Coordinate Systems

For a coordinate system to be useful, the programmer must be able to assign the origin to a convenient place relative to the part to be machined. To define the work coordinate system origin, the programmer can position the the machine to the desired point and tell the machine that the position it is currently in should be the work origin.

The position of the work coordinate systems are often stored in an “offset register” or “offset screen.” Most machines can accommodate several different coordinate systems. The programmer can ask the machine to use one of the work coordinate systems by specifying, for example, G54.

Enabling G54 through G59 is a common way to specify a specific work coordinate system. To specify the origin of, for example, G54, the operator would use an edgefinder or other probe to position the spindle over the desired origin (see below).